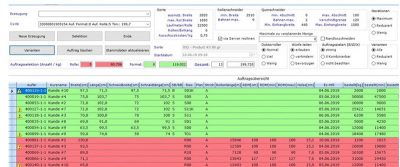

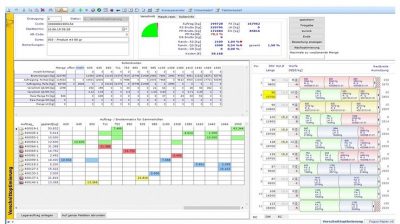

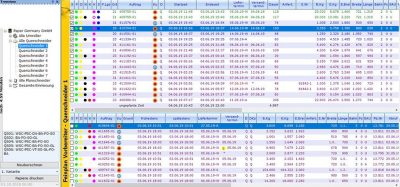

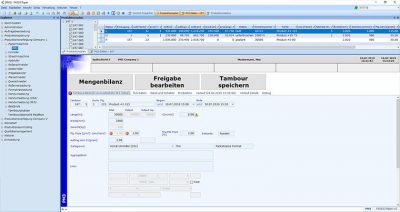

Rough Production Planning

With FAGUS, users get a top-level overview of the production process, while having the full flexibility to process order requests quickly, ensuring deadlines are met.

Order allocation is calculated based on the production quantities and completion date, resulting in reliable planning, short reaction times and total cost minimisation.

FAGUS allows you to define standard production plans that can easily extend the schedule on the timeline.